1

Followers

24

Following

AltPartsInc

Alternative Parts Inc. is the manufacturer and distributor of replacement parts for Amada Machinery and laser parts of leading brands like Amada Parts,Trumpf, Mazak, Bystronic, Prima Power, LVD Strippit, Mitsubishi, Cincinnati and Fanuc.

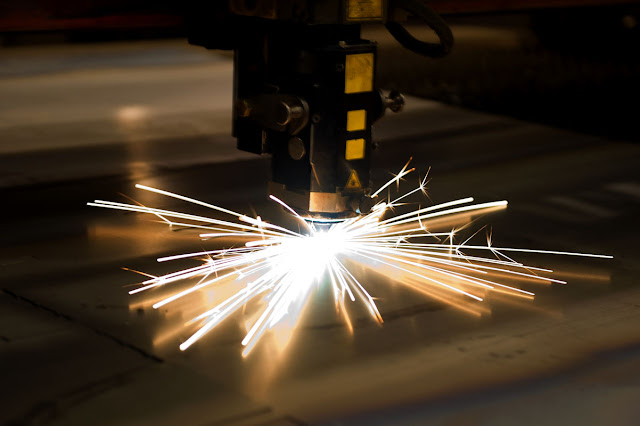

How to Maintain Laser Cutting Machines?

Never Leave the Laser Machine Unattended

One of the Laser Materials like acrylic is prone to catch fire when it goes unattended during the cutting process. There have been instances when people had to replace the whole laser cutting machine in cases of fire. To eliminate such cases, we need to make sure that someone is within 3 feet area all the time.

Keep the Lens Clean

Every fabricator has a different type of laser cutting schedule. Daily maintenance is one of the major things we need to make sure for the laser parts involved in the process. If you wish to replace any of them consider Mazak laser parts. They come with good quality features and provide an ample amount of cutting. One more thing to make sure that after the cutting schedule, check the lens and clean if necessary. As the top lens and mirror are right above the laser beam and exposed to a lot of dirt, smokes, debris, and fumes. With the dirty lens you might get:

- A need of lower speeds or higher power to cut.

- Uneven and blurry images.

- Damaged lenses

The simple way of cleaning the lens and mirror is removing it gently and cleaning both the sides with a q-tip or lens paper.

Clean out the Filters

With regular maintenance tasks, you need to maintain the filter as well. Based on its usage and the type of materials, you need to change the inner ‘pad’ pre-filer and clean the foam dust collector.

Here are the hints that indicate that you need to replace the filter:

- Smoke is collecting in the laser bay.

- Fire/flares in the bay.

- Odor emanating from the machine.

- The filter is dirty on both sides.

Here are the steps to follow to replace the filter:

- Open up the machine.

- You will see the inner filtration assembly inside. There would be a foam dust collector inside the metal mess. Since it catches the big dust particles, rinse this out in the sink and dry it out.

- There would be a wrapped pad pre-filter on the outside.

- You can buy new pre-filters and wrap them around.

Warranties are a key part of the buying process. If you are a fabricator and pursuing a maintenance contract or extended warranty, it is important for the purchasing department to have a complete understanding of points covered in it. Do the contract cover maintenance and parts? If yes then does it cover quality laser parts Trumpf laser parts? Is there any discount provided on any needed replacement part? How much more an emergency service call would cost without a contract? What are the possible limits of the contract?

Replace Charcoals

With the cutting, plastics, there are chances of developing odors. However, the pre-filer works the best to get rid of particle matter. But the Electrocorp also has 20 lbs of carbon particles. And they absorb the nasty smell. Eventually, the charcoal gets 'full' and doesn’t absorb fumes.

Some indications that you need to replace the charcoal:

- The smell of burning plastic is strong.

- Smoke sucked away.

- The filter is clean but the problem doesn't go away.

- The charcoal smells of fumes.

Final Thoughts

Maintenance of laser parts is varied by its usage and type. There is no one-size-fits-all solution to properly maintain the laser fabrication process. And while you replace the laser parts, you can find several options from the web if you write queries like ‘Trumpf laser parts’ and ‘Mazak laser parts. The maintenance lessons result in a more consistent, reliable, and cost-effective laser operations.