1

Followers

24

Following

AltPartsInc

Alternative Parts Inc. is the manufacturer and distributor of replacement parts for Amada Machinery and laser parts of leading brands like Amada Parts,Trumpf, Mazak, Bystronic, Prima Power, LVD Strippit, Mitsubishi, Cincinnati and Fanuc.

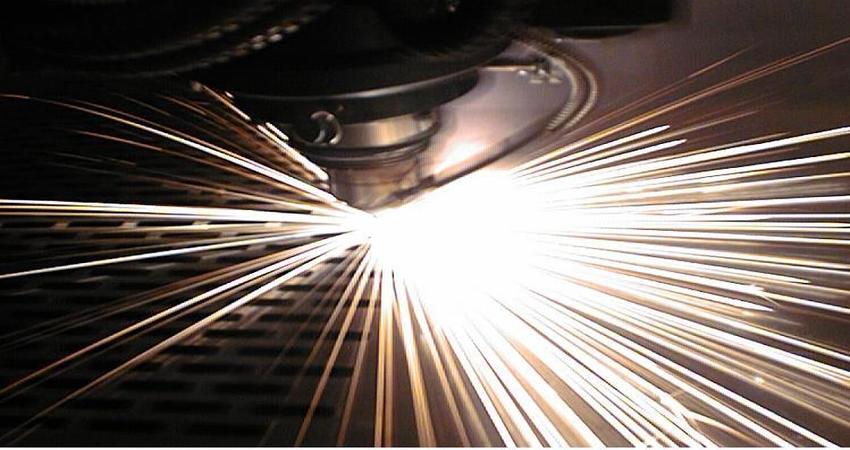

What Products Can a Laser Cutting Machine Produce?

Laser metal cutters are a life of any material production company as they can provide accurate and finest cuts. If you want metal outputs without excessive distortions irrespective of the thickness of metal, they are a ‘to go’ equipment. Even if these machines get old, the manufacturers often buy Bystronic laser parts and replace them with new ones so that they can start working like before.

Manufacturers also choose laser metal cutting over CNC punches because CNC machines use physical force for shear metal cutting due to which, there’s often some mechanical deformation in the final product. Today, we will try to know about the types of metal products that laser cutting machine can produce. So, here we go:

Cut-Out Parts

When you want to make small cut outs from large metal sheets, laser cutting works the best. Several industries make use of these cut-out parts for different purposes. It is possible to make mini fan blades, computer drive mounts and other flat aviation parts using CNC press brake or other metal cutting machine. The companies that sell Mitsubishi laser parts often sell CNC press brakes. So, it is easy to find it online.

Engraved Sheet Metals

If the laser cutting machine works at lower settings, you can use it for cutting a piece of sheet metal and give it a smooth finish with a groove on its surface. Through laser engraving, manufacturers can leave a distinguished and fine mark on the sheet metal. For example, if your customers want to create customized cake molds to place in the ovens of a particular size, the operators can make use of this functionality and engrave the metal of molds accordingly.

Sheet Metal Baskets

Some restaurant industries require wire mesh baskets for washing and frying food materials successfully. In some cases, they also need a strong sheet metal with holes inside it and several steel wires arranged horizontally and vertically. For cutting such intricate shapes and creating sturdy baskets, nothing but laser machines can come of use. However, the makers of these baskets need several years of experience to build them according to the defined standards.

Sheet Metal Tags

So, how do manufacturers recognize similar products/baskets from others? This is where metal tags come of use. Using metal tags, it becomes easy for basket users to identify one basket from other especially when they look similar to each other.

Why Should You Make Use of Laser Cut Parts?

The first and the biggest reason as to why you should use laser cut parts is that the parts get a professional finish. They don’t look like the operators have made them using mechanical stress. Not just that, the heat zone of the cut metal also looks quite small and cut metal piece looks as good as a new one. Also, when you do not expose the workpiece to heat, it keeps the property of the metal intact and minimizes the waste.

Some modern manufacturing shops need CNC punches when it comes to producing metal parts. At times, it is possible to create products like bent sheet metal perfectly by using CNC punch machines. It also helps with producing metal sheets rapidly.

Do you want to know more about laser metal cutting and Mitsubishi laser parts? Feel free to ask us. You can also read about sheet metal fabrication in detail and find out more about it.